In recent years aspirating smoke detection (ASD) systems have grown significantly in popularity. Originally considered as a specialist form of detection for sensitive areas, the installation of ASD systems has now become far more widespread across a wide range of sites including data centres, museums, hotels and warehouses.

As a result, fire maintenance companies are now being called upon to test more of these systems every week as part of their routine service and maintenance visits. So, with an increasing number of ASD systems being installed, what are the biggest challenges facing engineers as they look to carry out functional testing? We used our latest Twitter poll to gain some insight.

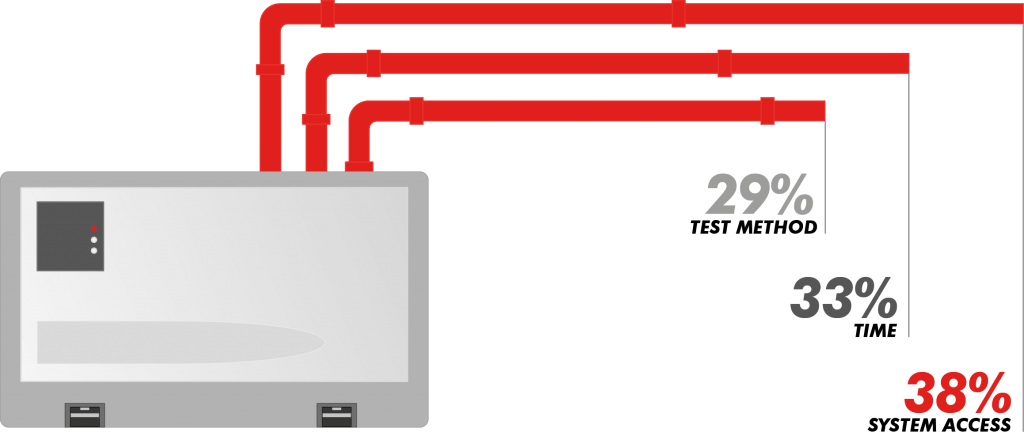

Our question: What is your biggest challenge when testing ASD systems?

The response was fairly equally split, with 38% commenting that the biggest challenge was with accessing the system, 33% siting time as the biggest challenge and 29% suggesting the test method presented the biggest hurdle.*

Testing doesn’t have to be difficult.

Our Scorpion solution enables simple testing of ASD systems installed in hard-to-access locations. Installed permanently on the pipe next to a sampling hole or at the end of the pipe run, the Scorpion unit is wired back to a conveniently mounted access point which can be used to initiate testing when required. In this way, testing a hard-to-access ASD pipe is easy and is completed in a matter of minutes.

Both Scorpion and Solo 365 have proved extremely popular with fire engineers and ASD system manufacturers – they overcome the challenges brought about by access, reduce the time spent testing the system and provide a reliable, fit for purpose solution that can be carried out as part of the routine maintenance visit.

*Results of a Twitter poll November 2017 @NoClimbProducts